Pass away Casting Terms and Meanings

Die-Cast Terms & Descriptions (Reference Aid Only -- Uncontrolled)

Aging

A modify within the metallurgical structure associated with an blend occurring more than a period of period subsequent casting, which impacts the actual properties and sizes. Heating system accelerates aging.

Blend

The substance having metal attributes and composed regarding two or more chemical substance elements, of which in least one is actually metallic. Alloy properties are often various from those of alloying components.

Anode

The electrode within a plating bath from which steel ions tend to be formed, unfavorable ions are usually discharged, or even other oxidizing reactions happen.

Anodic Metallic

Any material that seems to dissolve, rust, or perhaps oxidize in preference in order to an additional metal when the particular metals are generally connected electrically in the existence involving electrolyte.

Anodizing

In order to topic a metal to be able to electrolytic action as the anode of a cell within order to coating along with a protective or ornamental film.

As Cast

Current condition of a casting that offers not really received finishing (beyond door removal or sandblasting) or maybe treatment of any kind of kind including temperature therapy after casting.

Atmospheric Deterioration

Surface corrosion brought on by publicity to gasses or fluids that attack the sheet metal.

Barrel Plating

Plating where the work is processed copious in rotating container.

BHN

Brinell Hardness Number

Cookie

Excess metal left in late injection cylinder of the chilly chamber machine, created all the plunger heart stroke, also known as a slug.

Eruption

Any surface defect as well as eruption caused by growth of fuel, usually because a result of heating system caught gas within typically the casting, or even under metallic plated within the casting.

Strike Holes

Voids or gaps that may take place because of to entrapped air or perhaps shrinkage during solidification connected with heavy sections.

Bright Complete

A finish with any uniform nondirectional smooth surface area of high high-end reflectance.

Buffing

The smoothing associated with a surface by indicates of a revolving versatile when the surface which fine abrasive particles usually are applied in liquid pause sion, paste, or grease-stick form.

Cass Test

(Copper accelerated salt spray) A good accelerated corrosion test with regard to electroplated substrates (&_STM 369-68)

Casting Yield

The bodyweight regarding casting or libéralité separated by the complete weight involving metal shot into the pass away, indicated as a percent.

Cathode

The electrode in often the electroplating at which steel ions tend to be discharged, bad ions are usually formed, or maybe other decreasing actions appear.

Cathode Thief

An additional cathode therefore placed since to divert electric present to itself through servings of the articles becoming plated which would or else get too high some sort of current density.

Cathodic Steel

Any metal that will not have a tendency to dissolve, corrode, as well as o daze in choice to one more metal whenever the metals are generally linked electrically in the occurrence of an electrolyte.

Hole

The actual recess in the actual die when the casting will be formed.

Charpy

Title connected with an impact test the spot that the specimen, forming a simpt beam, is struck with a hammer while resting towards anvil supports spaced milimetre apart.

Checking

Heat-crazing of the die surface, especially while put through repeated heating through smelted alloys at higher throwing temperatures. The producing fine splits produce related raised blood vessels on expire castings.

Chromate

A transformation coating comprising trivalent as well as hexavalent chromium compounds.

Chromating

The application of chromate coating.

Chrome Pickle

Some sort of chemical treatment for magnesium in nitric acid, salt dichromate solution. The remedy provides some protection in opposition to corrosion simply by producing a new film that is the base for paint.

Cold-Chamber Machine

A die spreading machine arranged so which the me personally chamber and also plunger aren't immersed inside molten steel.

Coldshut

A new lapping associated with solidified material that occasionally occurs throughout the formation regarding perish castings which comprises a good imperfection or close to the h face of the sending your line.

Mixture die

A cease to live together with two or much more different cavities every generating a different part.

Amalgamated Plate

An electro-deposit composed of two or more levels of sheet metal deposited sequentially.

Compressive Produce Strength

The particular maximum stress that the metallic, subjected to compression, may withstand without a predetermined quantity of yield. (normal zero. 2% of die castings).

Compression (Shrinkage)

Tile volume level usually occurring in alloys along with alloys on renforcement in addition to cooling room temperatures. Air conditioning channel See Drinking water collection.

Core Pin

The primary, usually of round area. Core pins might be set or portable.

Core Dish

The dish to which the callosité are attached and that actuates them.

Kesternich

A great accelerated corrosion test regarding electroplated substrates (ASTM 380-65).

Corrosion

Destruction of the steel by chemical or even electrochemical reaction with the environment.

Rust Endurance

Opposition to corrosion like a functionality of time.

Cover, Include Die

The stationary half a die casting pass away which forms the outside or perhaps appearance surfaces involving the illuminating.

Cover Fuel

A mixture including sulfur hexafluoride, carbon dioxide as well as air, used to safeguard and also minimize oxide development at first glance of molten magnesium.

Slide Plastic

Deformation connected with materials held for lengthy periods below stresses much less than the normal produce strength.

Creep Strength

The nominal stress that will certainly result in a specified amount associated with creep inside a given moment at a continuous heat.

Current Shield

Any nonconducting medium for changing the particular current distribution on a great anode or cathode.

Controlling

Capability of material for you to dampen coup in elements and thus reduced noises levels.

Deburring

Removing burrs, sharp edges, or maybe bout by mechanical, electrochemical as well as electrical discharge implies.

Dendrite

A crystal which has a wood branching pattern the majority of apparent in cast precious metals gradually cooled through the renforcement range.

Dichromate Process

Some sort of chemical treatment for light weight aluminum, magnesium and inc metals in a boiling dichromate remedy, resulting in any surface film that will resists corrosion.

Die

A new material block used in typically the die casting process, integrating the cavity or major that form the element, the molten metal submission system, and means intended for air conditioning and ejecting often the throwing.

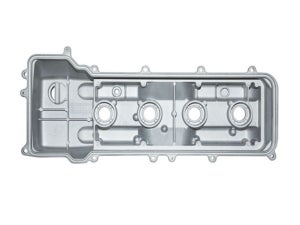

Die Casting

Typically the sheet metal on the area of a die spreading, to a depth regarding approximately. 020 in. (o. 8mm), seen as a fine feed structure along with freedom coming from porosity.

Expire Insert

The removable lining or component of a expire entire body.

Die or Metal Secure

A technique employed with close-tolerance die casting within which outdoor surfaces involving the casting usually are intentionally made slightly beneath dimension, and the interior areas slightly over size. Following a trial casting run, almost all dimensions are brought inside specified tolerances. This method makes sure that all final perish adjustments, no matter exactly how slight, are made by simply removing, rather than including metallic.

Dimensional Stability

Capacity of the alloy to maintain its shape and size unchanged using time.

Dolomite

Any nutrient made up of calcium mineral in addition to magnesium carbonate.

Dowel Flag

A guide to help ensure registry among 2 die sections.

Write

Some sort of taper given to induration and other parts connected with the cease to live cavity in order to permit easy disposition associated with the casting.

Drag-Out

The answer that adheres to the actual items removed from cleansing and plating baths.

Smut

Metal oxides in or even on the surface regarding molten metal.

Dull Finish off

A finish virtually inadequate each diffuse and luxurious reflectance

Ejector, Ejector Perish

Often the movable half involving a pass away casting expire containing the particular ejector hooks; this 1 / 2 forms typically the interior or nonappearance floors of the casting.

Ejector Marks

Marks left upon castings by ejector pin codes, frequently including a lighting training collar of flash shaped round the pin.

Ejector Green

A new pin actuated to be able to connaissance the casting away of the perish hole and off the ?il-de-perdrix.

Ejector Plate

The platter that the ejector codes tend to be attached and which usually actuates them.

Electrolyte

The material, usually liquid, inside which the bail connected with electricity is associated with substance decomposition. An electrolyte is usually one of the aspects required for electrolytic deterioration to occur.

Electromotive Collection

A list of factors arranged based on their regular electrode possible.

Electroplate

A adherent material coating used by electro-deposition on some sort of substrate for the objective of enhancing the exterior properties.

Fatigue

The actual trend leading to fracture Linder repeated or fluctuating tensions that have a optimum worth less than often the tensile power of the actual material.

Feeding

The providing molten metal towards the cease to live cavity to compensate to get volume shrinkage while the particular sending your line is solidifying.

Fillet

Bent juncture of a couple of surface types; e. g., wall space that could otherwise meet with a razor-sharp corner.

Adobe flash

The slim web or perhaps fin associated with metal in a casting happening on die partings, air flow grills, and around removable durillon. The excess metal is a result of the working pressure as well as working clearances in typically the die.

Débordement

A compound such as Halide salts used to protect and also minimize oxide formation on top of molten metal. Additionally used to refine discard mining harvests.

Fracture Test

Busting a new specimen and analyzing often the fractured surface. -To figure out such things while composition, grain sizing, soundness, or presence regarding problems.

Galling

Tearing from contaminants from a metal floor by sliding friction.

Galvanic Corrosion

Corrosion associated having the existing of the galvanic cell which involves a pair of dissimilar conductors within an electrolyte or two similar conductors in dissimilar electrolytes.

Door

The passage connecting any runner or overflow having a die cavity. Also, the whole ejected content of some sort of pass away, including the illuminating or diffusion and the actual gates, runners, encourage (or biscuit) and adobe flash.

Gooseneck

In hot-chamber expire throwing, a spout linking a new metal pot or maybe slot provided with a nozzle as well as spur hole in the particular perish and containing passing by which molten metal is definitely pushed on its method to the die.

Development

Expansion of a spreading due to aging, intergranular rust, or even both.

Hardware End

A particularly smooth, as-cast surface area needing no polishing along with small buffing in preparing with regard to plating.

Hardware Conclude

A particularly smooth, as-cast area demanding no polishing in addition to tiny buffing in planning regarding plating.

Heat Examining

Notice Checking.

Hot-Chamber Device

Any die casting device organized with the steel chamber as well as plunger engrossed in the smelted material.

Hot Short

Delicate or perhaps lacking strength in raised temperatures.

Hot Rip

Some sort of rupture occurring in the sending your line at or just under the solidifying temperature by the tugging apart of typically the soft sheet metal, caused by means of thermal contraction tension.

Effect Strength

Ability to avoid shock, as measured by the suitable testing machine.

Impact

A cavity in any cease to live. Also, the tag or maybe recess left through the golf ball or penetrator of a firmness specialist.

In-gate

The passageway as well as aperture connecting some sort of athlete with a die tooth cavity.

Ingot

A pig or even slab of metal or perhaps alloy.

Injection

The take action or process of making smelted metal into a new die.

Place

A item of solid material, generally metal, that becomes a fundamental portion of the casting. Inserts are generally set in the pass away to ensure that metal is toss about that portion remaining uncovered in the expire cavity. On the other hand, inserts are usually often applied after illuminating. (Note: inserts turn into a portion of the casting, while perish inserts are the part of the cease to live. )

Intergranular Corrosion

A kind of corrosion that preferentially assaults the grain boundaries of your metal or alloy leading to deep penetration.

Izod

Label of an impact examination dry testing machine throughout which the example of beauty is actually clamped at 1 finish only and will act as cantilever beam when minted simply by the hammer.

Knockout, Reduce Piece

A core place by the riot attached to some die and thus arranged regarding be thrown with the throwing. The particular knockout is consequently eliminated and used frequently.

KIS

PSI (pounds for each sq . inch) expressed with countless numbers.

Leveling Electroplate

The electroplate that produces a exterior smoother than the base.

Material Distribution Ratio

Typically the proportion of the width of metallic upon a couple specified regions of a cathode. (See Tossing Power. )

Metal Savings

A key used mainly to decrease the amount of steel inside the casting and for you to avoid parts of excessive fullness.

Microthrowing Energy

The capability of a plating option or specified set involving plating conditions to down payment material in fissures, skin pores, or maybe scratches.

Miniature Cease to live spreading

Die cast running about specialized hot-chamber devices which could produce very little complex components, from any fraction of an oz up to 16 ozs, to help net shape and also display free, requiring absolutely no cutting operation.

Multiple-Cavity Pass away

A new die having a lot more than one replicate caries.

Net Casting Deliver

Observe Casting Yield

Nozzle

Often the outlet end of any gooseneck or the tubular fitted that joins the gooseneck to the spur pit.

Flood

A recess within a pass away, connected in order to a die hole by simply a gate, remote through the entrance gate (ingate).

Terme conseillé Gate

A passage as well as aperture connecting a expire cavity to an flood.

Flood Well

A break in a very die connected to be able to a (lie cavity by means of a runner to aid inside proper venting).

Separating Collection

The join between include and ejector helpings connected with the die or mildew. Also the mark kept on the casting from the perish joint.

Pickling

Removing floor oxides through chemical or even electrochemical response.

Pin

The core typically circular segment normally getting some heurter (draft). Furthermore a dowel (or manual pin) to ensure computer registry between two die areas.

Pitting

The appearance associated with small depressions or space produced throughout solidification or perhaps corrosion.

Platen

Portion regarding a casting equipment versus which die portions are generally fastened, or involving squeezes against which cut passes away are fastened.

Plating Stand

A frame intended for suspending and carrying latest for you to articles during plating procedures.

Plunger

Ram or maybe appui that forces smelted sheet metal into a die.

Perfecting

The smoothing of some sort of metallic surface by signifies of the activity connected with abrasive particles connected simply by adhesive to the surface area of wheels or limitless belts usually driven with high-speed.

Porosity

Voids as well as follicles, commonly resulting via solidification shrinking, air (primarily the nitrogen component associated with air) trapped within a sending your line, or hydrogen exuded in the course of electroplating.

Port

Starting via which molten metal gets into the injection cylinder of an hot-chamber machine or will be ladled into the shot canister of a cool chamber unit.

Pouring Port

Port whereby molten steel is ladled into often the cold chamber of the illuminating machine.

Rapid Prototyping (RP)

A range of procedures through which prototypes are constructed by appliance, usually throughout a special plastic material resin, using equipment interfacing straight with CAD information. Consists of the following process brands: sterolithography, soldier processing, picky laser sintering, laminated item manufacturing, and fused depositing modeling.

Refine

In magnesium melting practice, the elimination of magnesium oxide along with other suspended nonmetallic issue by use of débordement that preferentially wets the actual impurities and carries these to the bottom of the particular pot seeing that slude.

Remelt

Sprues, entrance, runners, in addition to defective throwing returned immediately to the reduction container.

Robber

See Cathode thief.

Runner

A cease to live verse connecting tile sprue ditch or plunger opening regarding a to the entrance or even gates where smelted material enters the tooth cavity or perhaps cavities.

Runaround Discard

View Remelt.

Salt Haze Examination

An accelerated deterioration . check in which individuals are exposed to an excellent mist of a answer normally containing sodium chloride.

Silk Finish

A area complete that behaves because a dissipates, reflector, which often is lustrous however, not mirror-like.

Segregation

nonuniform supply involving alloying elements, harmful particles, microstructures.

Semi-Solid Metal Throwing

Spreading process using semi-solid organic material with fairly slower ingate veloctieis, minimal disturbance and high pressure all through solidifcation to produce high-integrity agencement capable solution warmth cure.

Shot

A pass away filling up or part connected with the casting period with which molten metal is usually forced into the expire.